Tag Archives: maintenance

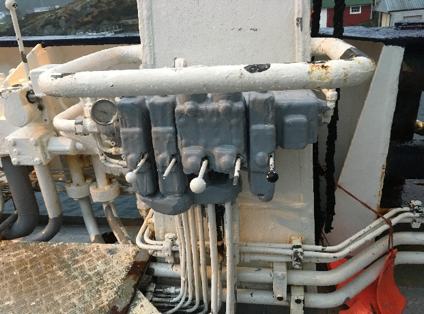

Case Study: Fishing Vessel Corrosion Protection

Oxifree TM198 is 100 percent environmentally friendly corrosion inhibitor supplied by Corrosion Solutions Norway AS. After a simple pretreatment, TM198 can be applied on structures using an applicator gun. The application is fast and efficient and can even be applied to live equipment eliminating the need for a shutdown. M/S Endre Dyrøy is the first vessel in Norway to have been applied with this unique corrosion inhibitor at 30 different objects/points. Most of the treated points had clear signs of corrosion, whereas some points were treated before they were corroded. Despite the fact that the vessel is well taken care of, part corrosion is a general problem that occurs on this type of vessel as these often operate in tough environments characterized by high humidity and salt. click here to read the story, see more photo’s 14:00

Ottawa investing $33.5M in British Columbia harbour improvement projects

The federal government announced it will invest $33.5 million to carry out harbour improvement projects — including wharf construction, maintenance and dredging — at 29 small harbours throughout B.C. “Small craft harbours are the hub for our fishing industry,” said Joe Peschisolido, Liberal MP for Steveston-Richmond, who announced the funding on Aug. 31. “Fish is actually now our second most important food export after wheat, and creates a lot of economic activity. If you want to create wealth … you want to have an efficient economy, you need infrastructure and small craft harbours are an integral part of our infrasturure. Almost a third of that funding will go to the Steveston Harbour Authority in Richmond, which serves over 500 commercial fishing vessels. Read the story here 16:12

Caterpillar – How Should I Care for my Cooling System?

![caterpillar-3208-diesel-engine[1]](https://fisherynation.com/wp-content/uploads/2016/04/caterpillar-3208-diesel-engine1-e1460313599613.jpg) The first step for cooling system care is making sure you’re using the proper fluids. Either distilled or deionized water should be used with an approved antifreeze and an approved supplemental coolant additive or rust inhibitor. (Fishermen in warmer climates don’t need to use antifreeze but must still use the coolant conditioners.) Use a low-silicate antifreeze that meets one of the following specifications: GM 6038-M or ASTM #D4985. The fluid in the jacket water cooling system should not consist of plain tap water or water which has been “softened” by a domestic water softener. Tap water is not recommended for engine cooling systems because of additives, contaminants and other chemicals (such as salt, chlorides, sulfates, etc.) found in the water. Read the rest here 15:03

The first step for cooling system care is making sure you’re using the proper fluids. Either distilled or deionized water should be used with an approved antifreeze and an approved supplemental coolant additive or rust inhibitor. (Fishermen in warmer climates don’t need to use antifreeze but must still use the coolant conditioners.) Use a low-silicate antifreeze that meets one of the following specifications: GM 6038-M or ASTM #D4985. The fluid in the jacket water cooling system should not consist of plain tap water or water which has been “softened” by a domestic water softener. Tap water is not recommended for engine cooling systems because of additives, contaminants and other chemicals (such as salt, chlorides, sulfates, etc.) found in the water. Read the rest here 15:03