Damage Control For Flooding (Some notes on what to do when you have that sinking feeling)

by John Johnson

In my experience if you work on fishing vessels long enough you will eventually find yourself on one that has a hole in it with water coming through (It happens fast). If you engineer fishing vessels you are going to be expected to have the skills to lead damage control efforts, repair crews, control flooding, and even seal off compartments in order to prevent sinking. All of this needs to be done in a hurry so putting a little thought into how you intend to deal with flooding in some of the areas of your vessel and taking stock of any emergency pumps, equipment, and the condition of water tight doors and compartment bulk heads may be the difference between life or death.

If your vessel has good watertight compartments, sea doors that divide areas that could be damaged by collision or grounding, good sized bilge pumps that service all compartments, regularly tested and functioning flooding alarms, and some good tools for repairing and plugging holes in the hull and sea water pipes you have a much higher chance of surviving a flooding emergency than a vessel that doesn’t. Keeping these valuable assets in good working condition for the day you need them is just as important. (A sea door that cannot be readily closed and made watertight quickly may not be of any use at all.)

Rather than write an exhaustive lecture on the topic that nobody will want to read I will recount here an example of a flooding event that I dealt with in my role as engineer of the fishing vessel Oceanic while fishing in the Sea of Ohkotsk in 1999. The Oceanic is a 170 foot house forward, converted mud boat (A supply vessel designed to deliver drill mud to oil platforms working in the gulf of Mexico.) It was converted to a crab boat and the old mud tanks were used for ballast compartments (Forward), crab tanks (Center), and fuel tanks (Aft). The Oceanic held a lot of crab pots aft of the centerline and needed ballast forward to offset the weight of them.

In the winter of 1999 the ocean just inside of the Kamchatkan Peninsula froze over quite rapidly causing the crew of the Oceanic to stack up a load of 600 crab pots and move south. During the work we ran into heavy ice floes due to high winds pushing the ice down onto our gear. The boat was tough and we could push through some pretty bad sea ice but not all sea ice is visible and below one of those ice floes was a large iceberg which we struck in the middle of the night. Unlike most of our impacts with sea ice when we hit the iceberg we struck so hard anyone standing up was thrown to the ground. It heaved the vessel to Port hard but did not stop the vessel. Our forward ballast compartments were flooded at the time making it impossible to inspect for damage.

As we continued to stack up the 600 crab pots we intended to move it became necessary to pump out the forward compartment in order to provide additional flotation. My attempts to pump out this compartment with our 4 inch bilge pump failed. With the pump running at full capacity the compartment could not be pumped out and the hatch and bulk heads for this compartment bulged from water pressure (Particularly while we were underway). It was apparent that we had suffered hull damage from collision with an iceberg and had lost one or more compartments because of it. The decision was made to get rid of the pots we had and meet our processing ship (Rybok Chukotki) to unload crab and shift weight on the vessel aft in an attempt to get our damage (Tears in the hull) up higher and therefore less likely to flood faster than we can pump. The following images were taken after all possible efforts were made to get the breached section of the hull up out of the water and were taken with a 35mm disposable camera.

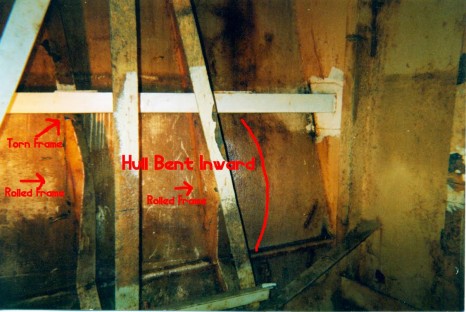

(1) This image was taken in the Port forward ballast tank of Oceanic which was not breached in the accident but suffered considerable damage from the collision. The iceberg went down the side of the vessel bending the hull inward and rolling and tearing the steel frames that give the hull it’s strength and integrity. The damage went on for three compartments but thankfully only flooded one.

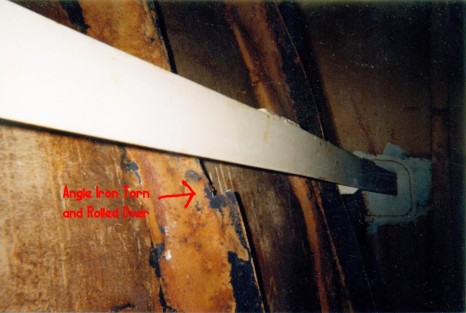

(2) The horizontal frame helped the hull maintain it’s shape but caused the longitudenal frames along it to tear.

(3) I took this picture after we finally caught up with the flooding and were able to gain access to the forward compartment. With the 4 inch pump running I dropped in through the hatch and this is the sight that greeted me. Water pouring in through the hull, cascading down to the bottom of the compartment and running like a river to the sump it was being pumped out of. My thought was, “Oceanic…Titanic…is there a similarity there?”

(4) Lucky for me we were able to slow the water down further and sometimes when the boat went up on a swell the water would even stop for a second.

(5) You can see here the tear in the hull extends right up to the bow and is not easily accessible. Looking down on the tear like this affords a view of the steel pushed inward on the bottom of causing a very wide gap to fill.

(6) I had to cut the frames to get at the tear. I could have used George Clooney’s torch from, “The Perfect Storm,” (That thing was like a light saber) because mine kept going out every time water came spewing through that tear. I waited for the boat to pitch upward on a swell to get this picture of the tear without water obstructing it.

(7) This weld repair made with water coming in was very difficult to do. I managed to span the gap with just welding rod and round bar which I would push into the gap to slow the water down, tack it in good and then beat it into the gap then weld it so hot that it would become part of the weld bridging the gap between the hull plates. For a larger hole with more water coming in I would try using wedges instead of round bar. Set up wedges are cheep and would do nicely to stop water and provide something to weld to for a good temporary repair.

(8) Here I have completed the repair and welded the frames back in. I even ground the visible portion of the hull weld smooth (Probably for the picture). This repair held together for 4 months of winter time crabbing and when they were repairing the vessel in Seattle the shipyard wanted to leave it and put a plate of steel over the whole area… I insisted they re-weld the tear as I felt that the integrity of my weld was suspect due to it being performed with water coming in.

(9 )This is me welding up the hull of Oceanic (Image taken by Russian Engineer Sergei). I was wearing rain gear while welding with water coming in but by the time this image was taken I had stopped all flooding as was doing cover passes so I took my gear off to try to prevent getting holes in it from sparks and stuff.

Engineers Notes…

There was no coast guard in Russia…. there were no choppers on the way to rescue anybody. Engineering crab boats out there was living on the edge where failure is likely to mean death. We never thought twice about what we had to do, and my advice to anyone dealing with flooding is that you shouldn’t either. Do all you can to stop or slow down flooding without hesitation.

Early detection is crucial. When the flooding alarm goes off you want to arrive in time to see where the water is coming in and get bilges pumping out and something stuck in the hole. Anything will do a piece of canvas, wooden wedges (Which can be made in a hurry with a skill saw and some wood), wooden dowels, steel wedges, tarpaulines, even bedding and pillows can slow water down and buy you time.

If you have to seal off a compartment in order to keep water out of the rest of the boat you can still try to plug the hole from outside the boat. A guy in a survival suit and a down line with a weight on it can be used to work on a relativy high hole but before doing that try a tarpauline with a light weight tied on two corners. If the tarpauline deployed by the damage gets up against breached hull with water pouring through it will be pulled into the gap slowing the flooding.

Pumping out fish and ballast tanks to lighten the boat (Providing more flotation) should be done carefully due to the possibility of de-stabilizing the vessel. If you have partially flooded compartments and elect to pump out a fish or ballast tank you could cause a stability emergency making the vessel lose it’s ability to right itself. In this condition the vessel will lean over to one side and stay there or roll completely over.

Once a vessel has lost stability or has uncontrollable flooding with no means to prevent sinking it is time to abandon ship. While I would tell you to be fearless and without hesitation in the face of flooding that has been detected early and offers a chance of success if you act quickly, once flooding has become advanced it is time to be careful. If the weather is bad that time will come sooner due to a lack of stability with flooding, loss of propulsion, and loss of steering. Even in calm weather a vessel can roll over quickly if flooding de-stabilizes the vessel due to partially flooded compartments creating too much, “Free surface effect.” A completely flooded compartment (Hopefully sealed off) is a lot less of a stability concern than a bunch of partially flooded ones.

The rest of my notes on the matter are going to require another article….

Till next time… Be safe out there. JJ

Leave a Reply